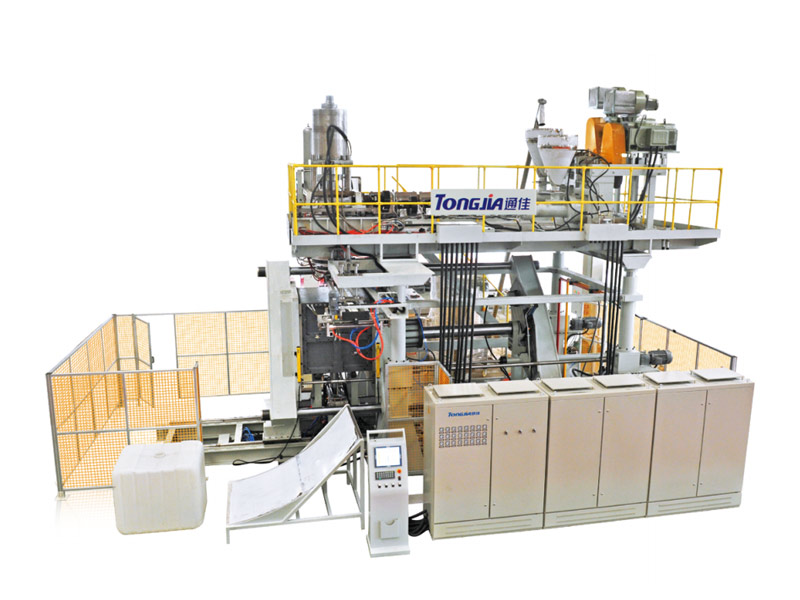

Tongjia TJ-KB2000IBC Large Blow Molding Machine is mainly used to produce industrial IBC packaging tanks, blow molding type pallets, water tanks, amusement facilities, etc. The imported parison control system ensures the uniformity of container thickness and meets the needs of users for different products.

| Clamping system: diagonal double tie bar center clamping bi-directional synchronous high-precision linear guideway clamping device. |

| Die head: single cylinder center-feeding accumulator die head. |

| Extrusion system: AC speed control + hard tooth surface reducer. |

| Hydraulic system: fully imported hydraulic valve + hydraulic servo control system |

| Control system: imported PLC + Europe imported complete machine control system (GEFRAN, Italy) |

Note: the above data are for reference only. The company reserves the right to change the components and mechanical structure. The relevant contents involved in the purchase of equipment shall be subject to the contract.